History

UKL was established in Taipei in 1987. Since its founding, our corporate goal has always been to provide our clients with the highest quality apparel products. Over the years, we have consistently kept focused on our core, specialized fields—sweater and knit wear. For this reason, we have become a highly trusted leading supplier in Asia, North, South Americas as well as Europe.

From our Taipei head office, we manage a network of more than fifty production lines spreading out in four different countries including Mainland China, Indonesia, Vietnam and Cambodia. Aside from our strength in manufacturing, UKL’s design capability has also won high acclaim from our clients around the globe, we has been able to forecast the current and future fashion trends. Keeping in mind the importance of a reliable and strong manufacturing base, we never stop perfecting our design power and UKL is in a highly competitive position to deliver unique designs sought after by our valuable customers.

The fashion industry is the second major pollution source in the world, next to the oil industry

According to a report by McKinsey, a business consultant, it indicates that more than 10 billion clothes are consumed worldwide every year. There is about 920 million tons of waste in refuse landfills that come from the fashion and textile industry. Moreover, according to a report in 2017, it was discovered that about 35% of the micro plastic pollutants are discharged when washing synthetic textile products. Most of them are the outputs of quick fashion.

According to the data of GREEN PLACE, the textile products discarded by Hong Kong residents every minute equal to one thousand T-shirts.

It requires land and water and plenty of materials such as chemical dyes, paints, etc. to produce clothes. It may be toxic along the entire production chain. When washing clothes, plastic fibers will flow into rivers and oceans with the discharged water. It will also discharge massive carbon dioxide when producing them. If the mass-produced clothes cannot be sold out, it will cause another major problem. It requires high price to bury these clothes, and it also needs to use the precious land to bury them.

Since from above situations, UKL join BCI Cotton Organization from 2018. We are BCI cotton member. We also be a member of GRS organization from 2021. We focus on substantiable yarn and material during our development stage. When developing new products, we insist on using environmental-friendly and recyclable materials (such as GRS yarn). Regarding dyes, our supply chain holds certificates that comply with the OEKO-TEX Standard 100 of EU.

UKL was established in 1988 in Taipei, Taiwan, specializing in the export of sweaters and knitted garments. With more than 30 years of experience, in Taiwan, we have won high acclaim from the customers. More importantly, we are a company that regards sustainability as one of our major goals.

Our production bases are in China (Shandong, Dongguan, and Hunan) and Southeast Asia (Indonesia, Cambodia and Vietnam), with more than 30 cut and sewn production lines and the manufacturing capacity of 500 computerized sweater knitting machines.

Our factories passed COSTCO GMP factory inspection and certified by WRAP, WALMART and BSCI.

Our competitive advantages: we use high-tech R&D capacity and manufacture at production bases in a choice of countries. Prompt in handling orders. Our supply chains endeavor to perform the best from yarns to finished products. We offer reasonable prices.

Production Units

OEM Service

With more than 30 years of professional skills in textile garments, our places of production are located in Southeast Asia, namely Vietnam and Cambodia. We are able to offer tax free advantages to our customers in Europe, targeting production process that generates competitive prices. Our strong sales team and supervisors in the factories collaborate to ensure that the products’ quality meet customers’ demand so that they can focus on sales and brand management.

Southern China – Dongguan Plant

Sweater factory with 32 computerized knitting machines

(12GG 14GG)

Northern China – Shandong Plant

Sweater factory with 78 computerized knitting machines

(3GG 5GG 7GG)

Indonesia production line

Sweater factory with 50 computerized knitting machines

(5GG 7GG 12GG)

Vietnam production line

Knitting factory (13 Lines-Cut and sew knit production Line)

Northern China – Shandong Plant

Sweater factory with 78 computerized knitting machines

(3GG 5GG 7GG)

ODM Service

ODM Ability(In house design team)

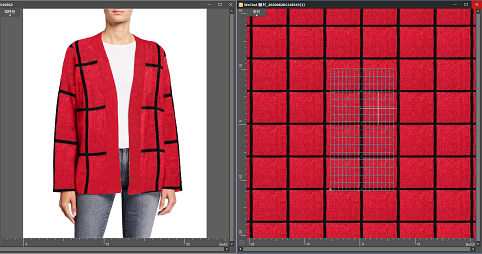

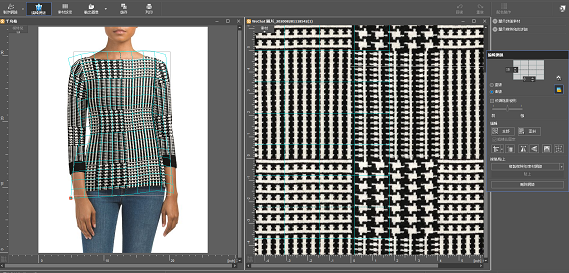

CLO 3D Simulation system

In addition to OEM services, we also provide ODM design and planning services to offer customers first-hand information before the next season to help them plan the concept development for the next season. Before the coming of the next season, we will actively provide information from expos worldwide, sourcing of related materials in Asia, and information on the latest design. We can custom make sourcing, design and planning services to our customers.

CLO function

CLO can simulate fabric drape accurately, for example, light plain and knitted fabric with different physical attributes. It is possible to see the effects immediately by visiting the CLO textile database. We can apply the techniques of stitching interlining, adhesive tape, block and seam, etc. according to customers’ demand to adjust the fitness of 3D clothing.

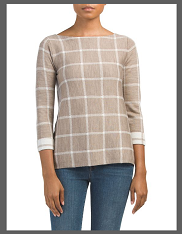

APEX4 3D Design System

APEX4 3D Design System

In the fashion industry, to cope with the changes in market demand, the “time and speed” from planning to marketing have become the important issues. The processing speed of SDS-ONE APEX4 in design and simulation is 6 times faster than old model machines, capable of satisfying the above demands. Designed with AI imaging function and other advanced technology, it is equipped with special functions for the planning and design of fashion and garment products. The ultra-real VR samples save the cost, time and materials for sampling. It can also create basic programs for plain knitting machines to achieve planning directly associated with production.

Low Minimum order quantity

Uniform production

Timeline

1987

UKL starts in Taipei, Taiwan.

1990

UKL moved to MinZu W. Rd., Taipei, and expanded the business to exporting yarn products, sweaters and ready-made apparel products.

2001

UKL won “2001 International Supplier of the Year” award from soft line department of Wal-Mart.

2003

UKL moved to Nei-hu industrial park in Taipei.

2004

UKL established Shanghai branch office in China.

2006

UKL won “2006 C&A MEXICO Star Supplier” from C&A.

2009

UKL affiliated company—UKL China Co., Ltd. was established in Shanghai.

2010

Judy Tsai, our GM, had won 2010 Golden Peak Award of Outstanding Enterprise Initiators of the Year in R.O.C.

2011

UKL China Co., Ltd. established Dongguan branch office.

2012

UKL won “Best Improved OMU Supplier” from C&A China.

2014

UKL established Shandong branch office in China.

2015

UKL affiliated company-Gain Victory was established, focusing on knit products.

2016

UKL headquarter moved to Xizhi U-Town.

UKL affiliated company-Yantai Deling Knitting Co.,Ltd. was established, providing low MOQ production service.

社會公益

2022.01.21

Charity concerts and caring sponsorships

UKL is doing charity work in remote areas, sponsoring children living.